Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

SHOE MAKING MACHINERY

SHOE MAKING MACHINERY

(241)WRINKLE-REMOVING AND IRONING MACHINE

This machine is applicable to the processing and finishing of leather shoes, and the wrinkle removal and leveling of the leather surface and inner lining.

SIDE SEAM SEWING MACHINE

This factory shoe sewing machine is not only can stitch one type of shoes,but also can sew many different shoes like sports footwear,slippers,british style fashion shoes,etc.

OUTSOLE HEAVY DUTY SEWING MACHINE

Suitable for heavy soles and heavy work boots edges suture and right-angle perimeter shoes to penetrate seam processing.

VERTICAL SHOE INSOLE MAKING MACHINE

Applicable to all kinds of shoes out sole and help the thoroughly,especially suitable for sewing processing orsin more strands of sewing thread.

COMPUTER ENERGY-SAVING ROTARY STEAM HUMIDIFIER

Characteristic: 1.The machine adopts 360-degree spiral design, the rotating distance of the heating closed area can reach 13 meters, the heating temperature is even to ensure that the best effect is kept after the shoes enter the heating area, and the quality is effectively improved. The effect is more than twice that of the traditional sulfur-adding machine, saving about30% of the electricity than the traditional heating machine. 2. Innovative Double Helix multi layer disc track design, smaller size,shorter fuselage. 3. The intelligent man-machine interface can automatically collect and save the data, and can switch the operation of the interface test equipment according to the customer's requirement. The operation is simple and convenient for information management. 4. The chain adopts precision cast 304 stainless steel and 304 stainless steel bracket to ensure smooth and durable operation of the machine. 5, the use of aviation-grade high-temperature plastic large pallet, more durable than other manufacturers, the failure rate is lower. 6, Patent anti-jump chain, anti-card chain design. Make sure the chain runs smoothly. 7.Add Steam. 8, the whole machine warranty for one year, rotating chain warranty for two years.

HIGH SPEED SPIRAL PLATE TYPE COOLING SHAPING MACHINE

Main features: 1. Using the principle of aerodynamics, cold air in the closed circulation,completely isolated from the outside air. 2.Special flow duct high speed cycle operation in 5-8 minutes to reach0 to 10 degrees below. 3. Setting temperature effect can be compared with conventional freezing10 degrees (low temperature and surface and shaping of about temperature of shoe uppers). 4. Only 1 sets of refrigeration compressor can achieve the effect of conventional freezing and shaping, can save up to 30%.

WET STEAMING MACHINE

Duct with jet design,special stainless steel heating chamber.High-speed convection hot air and steam,the upper mores tickers last completely changed the traditional process,maintaining flexibility and gloss leather.

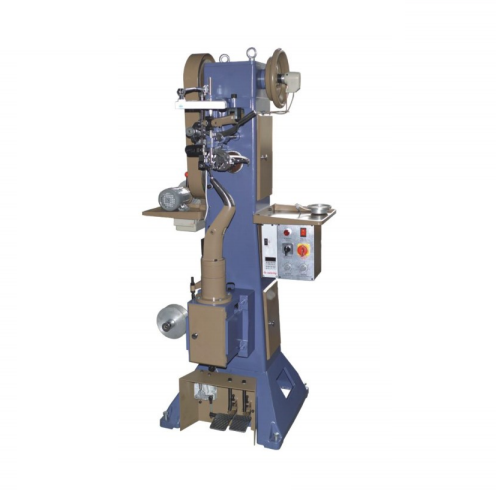

HIGH SPEED ENERGY-SAVING COOLING SHAPING MACHINE

This machine adopts the technology of Italy and the united states original imported compressor and the united states original accessories.

HIGH SPEED REFRIGERATING MACHINE

CHARACTERISTICS ◆ For shaping process of glue-cement-shoe after it attached with outsole, the machine is a necessary and advanced equipment to produce good-quality sports shoes, travel shoes and fashion shoes. ◆ Big power refrigerant system with close structure for air circulation, can make the temperature descend down to – 25℃, and the machine has auto-defrosting device as well. ◆ Special designed conveying belt movingly let the bond polymerized at a ideal effect. ◆ Refrigerant room was made up from adiabatic materials,it well keeps low temp-erature to promote the level of afficient energy. ◆ Temperature-setting function helps shoes get the best shape at the suitable degree after pulling out from last, and they are not easy to get moldy as finished products. ◆ The processing period is short, the lasts can be used in a high efficient way.

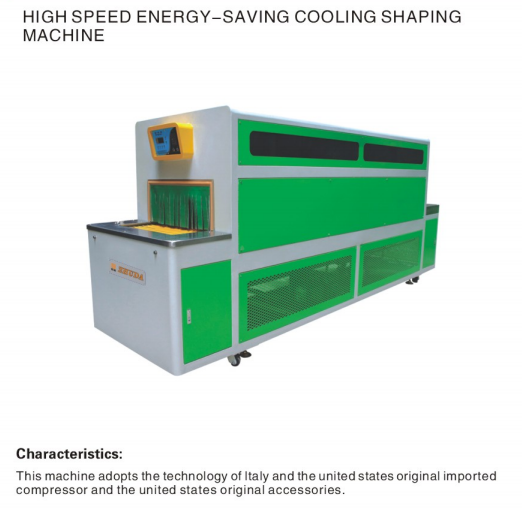

ROTATING SEWING PRODUCTION LINE

CHARACTERISTICS ◆ Scientific design for high-efficiency manager,this lime arranges labor positions of distrbuting materials,trimmer and return. ◆ The electrization procedure is resily to operate ◆ Save lobor in link of passing on,orderly control improve the working efficiency. ◆ It can be custom-made under different requirement of workshop space, intending output, functions distribution, labor positions etc,.