Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Shoe sole making machine series

Shoe sole making machine series

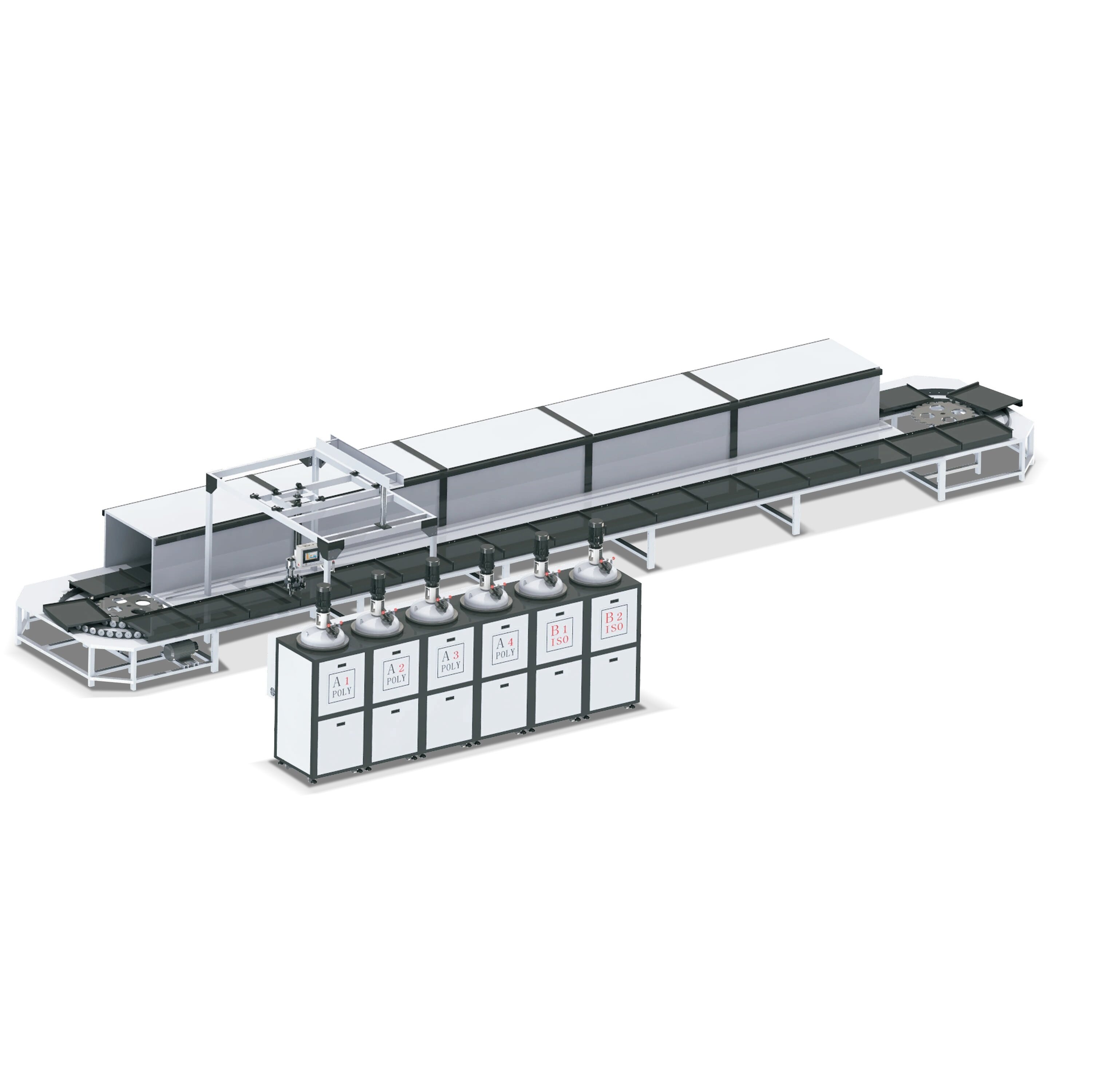

(14)MANUAL GANG UP / SOLE SOLE POLYURETHANE CASTING MACHINE

1.Adopting spiral and geared combination mixing device , which makes the mixture of materials liquid more evenly stirred and better to med out 2.Rotation speed of stirring n=9400r/min. The materials evenly mixed to produce delicate products with better elasticity : 3.If equipped with external coloring device, it can manufacture poly urethane products of varity of colors : 4.Acooling device is adopted to ensure nomal performance and lengthen service life ; 5.The machine work for long time continuously with low frequency of mixing head cleaning. lt reduces production cost, relieves environmental pollution and makes the products more competitive.

FULLY-AUTOMATIC DISK TYPE INJECTION MOULDING MACHINE

1.Use energy saving servo motor together with mechanical design can be save power 50%. 2.Brand new control system.ensure produce no edges and premised on the basis no deformation,the production up to 7500 pairs one day and ensu re la rge-tonn clamping force of mold. 3.Brand new model three colours with only two only two people operation,two colour only one people operation. 4.Use 4.6.8.12.16.20 stations machines for different customers with the mould individual cooling system and with fan cooling can be have high efficiency. 5.Use different design clamping force 80T 100T 120T 150T 200T for different model and material selection.To achieve quality of product. no deformation.no edges no surface treatment.no defects.no node linking and color uniformity.

ENERGY-SAVING SINGLE-COLOR PLASTIC SOLE INJECTIONG MOLDING MACHINE

1.Injections adopt import electronic scale to control the injection volume which can assure measurement accuracy. 2.The machine is driven by whole electric liquid servo system with fast-response and energy-efficient. 3.Adopt the automatic computer control system with touch screen control system which can be easy to operate and check freely.

ENERGY-SAVING 2-COLOR PLASTIC SOLEIN JECTION MOLDING MACHINE

1.Injections adopt import electronic scale to control the injection volume which can assure measurement accuracy. 2.The machine is driven by whole electric liquid servo system with fast-response and energy-efficient. 3.Adopt the automatic computer control system with touch screen control system which can be easy to operate and check freely.

RUBBER SOLE HYDRAULC MACHINE

1.The unique structural design of the fuselage not broken,not deformation,prolong the service life of the machine. 2.Using PC and PLC controller can operate independently,without mutual interference of containment. 3.The number of bleeding,bleeding time can be set free the operation are very convenient adjustment. 4.Pressure relief,deflation,falling action all can be adjusted independently 5.Oil pressure control using logic circuit less analysis of piping pipe is also less not easy to leakage pres sure keep constant. 6.Emergency lowering switch can the emergency stop and drop to moulds and finished products protection personnel the.

UPPER WELTING MACHINE

This machine is used for sole welt bonding process suitable for forming sole,fashion sole welt installation, production and processing.The fitting standard is consistent the operation is simple and easy to understand the product quality and work efficiency are improved and the labor cost is reduced.

SHAPED SOLE GRINDING MACHINE

For grinding the periphery of shaped sole. Function:to roughing the periphery of sole to facilitate the adhesion.

EVAARC SHAPING MACHINE

This machine is applicable for arc-shaping process of EVA foam sole,to get a curve on the EVA foam out sole the same with that of shoe last thorough specific former. It features simple operation high automation, high efficiency,etc..

AUTOMATIC EVA INJECTION MOLDING MACHINE

1.INJECTION SYSTEM: Injection system measurement and inspection bodies using a potentiometer with PLC and PC operation can be precisely controlled amounts.Injection shift seat slide mechanism using a linear motor with brake is driven by the inverter displacement speed control; positioning mechanism using a rotary encoder to detect the exact location. 2. MOULD CLAMPING SYSTEM: The two-stage clamping system Fast opening and closing mechanism includes a detection unit is completely closed mold. Low operating platform to accelerate the opening stroke elastically using various forms of molds.

GRINDING MACHINE

This machine is applicable for grinding polishing and shaping of out sole periphery.The out sole periphery may be processed into different shape and size and surface effect by rotating the grinding wheel and diamond wheel at high speed.It has features as high precision rotation good stability,less oscillation and convenient use.